Marble & Granite Quarries in the USA: Where American Stone Comes From

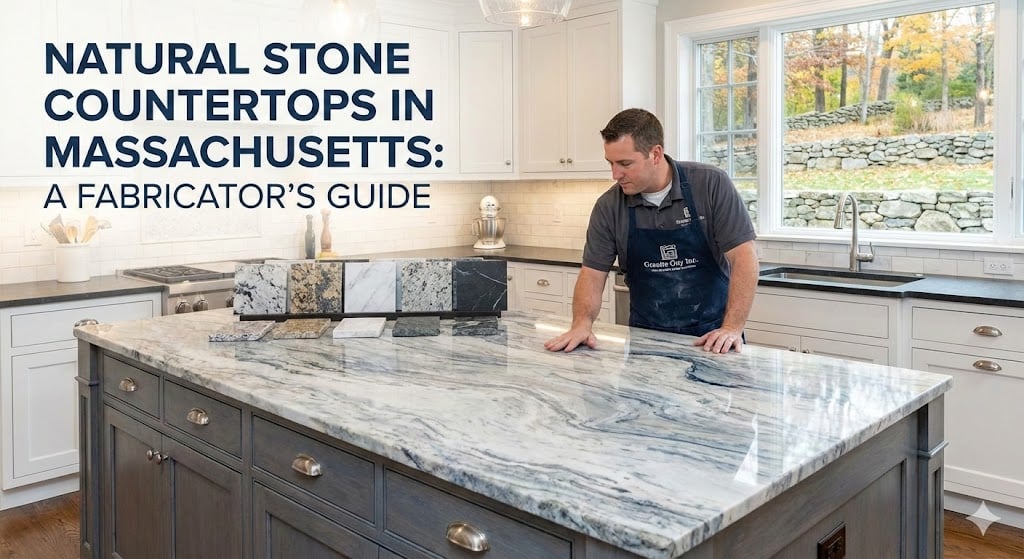

Written by Granite Guy Inc., Southborough, Massachusetts

Updated: January 2026

Most natural stone countertops in American homes come from Brazil, India, and Italy. But the United States has incredible quarries too, including the largest open-face granite quarry and the largest underground marble mine in the world. We also have historic soapstone quarries in Virginia and Vermont.

Whether you're researching where stone actually comes from, curious about American quarrying history, or wondering why most countertop stone is imported, this guide covers everything about US granite and marble production.

📊 US Granite & Marble at a Glance

- 276 active quarries in 34 states

- 580,000 tons of granite produced annually

- 90% of residential stone is imported

- World's largest granite quarry: Mount Airy, NC

- World's largest marble quarry: Danby, VT

In This Article:

🪨 Where Is Granite Found in the United States?

Granite is quarried in 34 states across the country. But five states do the heavy lifting: Texas, Wisconsin, Massachusetts, Indiana, and Georgia.

These five states produce about 64% of all American granite. Together, they pull roughly 580,000 tons of stone from the ground every year.

The US has 276 working quarries producing granite and marble for buildings, monuments, infrastructure, and countertops. Some are massive open pits visible from miles away. Others are underground operations carved deep into mountains.

✦ Why Most American Granite Isn't Used for Countertops

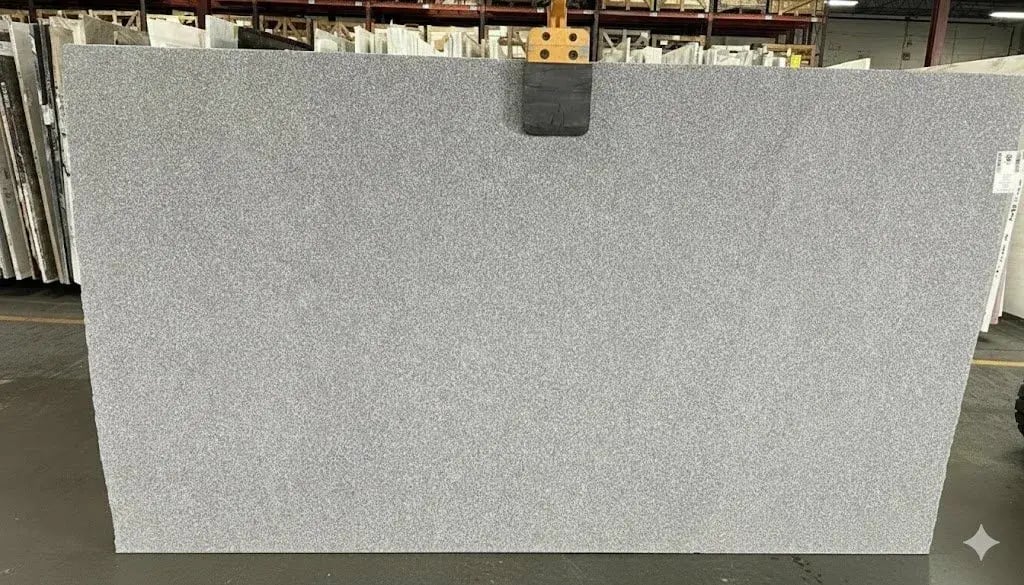

Here's something most people don't realize: the majority of American granite is plain gray.

That's perfect for structural use, paving materials, and monuments. But it's not what homeowners want in their kitchens. People want dramatic veining, exotic colors, and unique patterns.

Brazilian and Indian quarries produce blues, reds, and multi-colored granites that make statement countertops. They also supply most of the world's quartzite. American quarries focus on what they do best: reliable stone for large-scale commercial and infrastructure projects.

🏔️ Top Granite-Producing States

✦ North Carolina: Home to the World's Largest Granite Quarry

Mount Airy, North Carolina calls itself "The Granite City" for good reason.

It's home to the world's largest open-face granite quarry. When we say large, we mean massive. You can see the excavation from miles away.

The North Carolina Granite Corporation has operated this quarry since 1743. That's over 280 years of continuous work at the same site.

The quarry produces dimension stone, which is natural stone cut to specific sizes. It goes into commercial buildings, monuments, and paving materials across America. Mount Airy shows how the stone industry shaped entire communities for generations.

✦ Texas: A Granite Powerhouse

Texas ranks among the top five granite producers in the country. Quarry sites dot the state, extracting significant amounts of stone annually.

Most Texas granite serves infrastructure: dimension stone for construction, paving materials, and roads. The color is mostly gray, which works great for commercial projects and exterior use but doesn't excite homeowners shopping for kitchen countertops.

Texas quarries focus on producing reliable stone for large-scale projects. The paving materials from Texas line roads and sidewalks across the country.

✦ Massachusetts: The Hidden Granite Powerhouse

You've seen Massachusetts granite even if you don't realize it. The state's quarries have supplied stone for buildings and monuments across New England for over 200 years.

Chelmsford Gray lines the streets of Boston and surrounding towns. Those gray stone curbs along the roads? That's Chelmsford Gray. It's been the go-to choice for paving materials and infrastructure for generations.

Milford Pink granite is even more famous. Look at Boston's historic buildings and monuments. That warm pink stone catching the light? That's Milford Pink from local quarries.

These stones weren't chosen for being flashy. They were chosen because they last. After 100+ years of brutal New England winters, road salt, and constant weather changes, Chelmsford Gray curbs and Milford Pink buildings still look great.

As a Massachusetts fabricator, I see this stone history every day driving through Boston and the MetroWest area. Learn more about our company and how we continue this tradition.

✦ Wisconsin and Indiana

These states quietly produce significant amounts of granite. Multiple quarries harvest dimension stone for infrastructure and commercial construction.

Most of their output goes to construction and paving materials rather than residential countertops. Their focus is on exterior use: buildings, monuments, and public projects throughout the Midwest.

✦ Maine: Deer Isle and Coastal Granite

Maine has a deep history with stone. Coastal granite quarries have operated here for generations.

Deer Isle Granite is special. Unlike the plain gray used for paving, Deer Isle features beautiful colors and has gone into landmark buildings across America.

Maine's coastal quarries supplied stone for major projects throughout history. The tight grain and natural beauty made it worth the premium price. Many island quarries have closed, but Maine's reputation for quality stone remains.

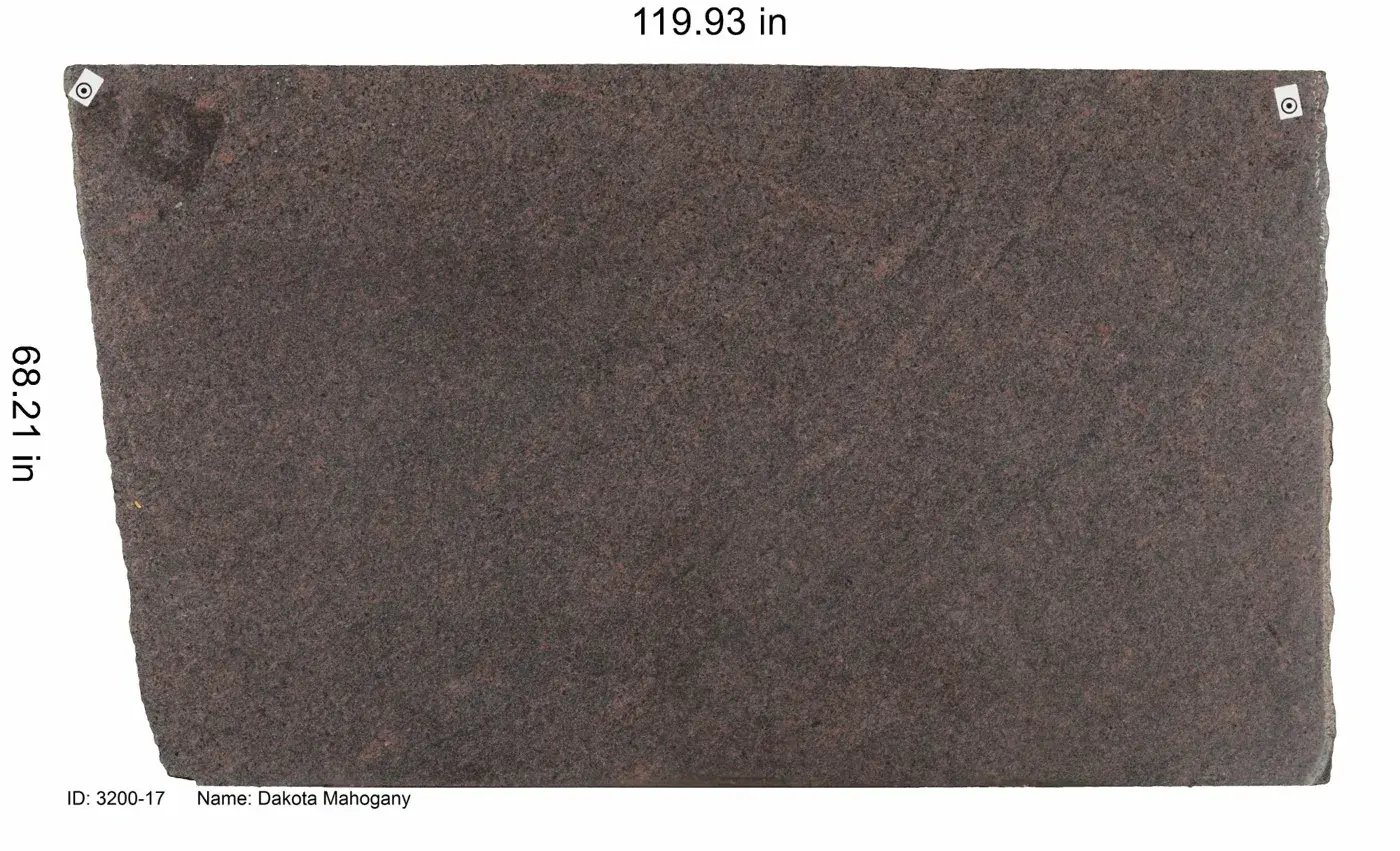

✦ South Dakota: Dakota Mahogany

South Dakota doesn't produce huge volumes. But it makes something special: Dakota Mahogany.

This natural stone is gorgeous. Rich red tones. Warm burgundy colors. It stands out from typical gray granite.

Dakota Mahogany goes into monuments, memorials, and architectural features where looks matter. It proves American quarries can produce beautiful, colorful stone, just not in massive quantities like Brazil or India.

✦ Virginia: Granite for Actual Countertops

Virginia produces two of the most popular American granites for kitchens: Virginia Mist and Jet Mist.

Virginia Mist is a beautiful gray and white stone with subtle movement and speckling. Unlike boring plain gray granite meant for paving, Virginia Mist has character. Each slab is unique. It's affordable, durable, and actually looks good on countertops.

Jet Mist goes darker. Deep charcoal background with lighter deposits and gray swirls. Sophisticated. Homeowners love it for kitchens when they want dramatic dark stone without high maintenance.

These prove an important point: American granite quarries can produce beautiful countertop stone. The issue isn't quality. It's variety and volume.

✦ Georgia's Granite Belt

Georgia quarries have supplied stone for some of America's most famous buildings. The "Granite Belt" produces dimension stone known for durability and consistent color.

Georgia granite has built monuments and government buildings across the nation. The stone represents American quality and reliability.

🏛️ Major Marble Quarries in the United States

✦ Vermont: The Underground Marvel

Vermont has something incredible: the Danby Marble Quarry. It's the world's largest underground marble quarry.

For over 100 years, Danby has produced America's finest marble. The operation goes deep underground, with chambers large enough to hold a football field. The quarry stretches about 1.5 miles into Dorset Mountain.

Stone from Danby has gone into iconic monuments you've definitely seen. The Jefferson Memorial. The Supreme Court Building. The United Nations Building. Arlington National Cemetery's Memorial Amphitheater.

Danby marble ranges from pure white to subtle gray veining. People prize it for clarity and consistent quality. The low absorption rate (0.06% to 0.08%) makes it less likely to stain than other marbles.

Vermont also produces Verde Antique. Technically it's serpentine, not marble. But builders have quarried it for over 150 years and used it in prestigious buildings nationwide. The distinctive green color makes it instantly recognizable.

Vermont marble shaped American architecture. When builders needed stone meant to last centuries, they chose Danby.

✦ Colorado's High-Altitude Marble

Picture a marble quarry at 9,300 feet above sea level in the Colorado Rockies. Discovered in 1875, it's still operating.

The stone? Calacatta Lincoln marble. The same natural stone used in the Lincoln Memorial.

The logistics are challenging. Quarrying marble nearly two miles above sea level, in harsh weather conditions. But the quality justified the effort. Calacatta Lincoln from these mountain quarries is some of the finest American stone ever produced.

✦ Other Marble-Producing States

Vermont and Colorado get the attention, but marble comes from other states too:

Georgia produces creamy white marble. Tennessee offers pink and gray varieties. Alabama has historic production. Missouri's Carthage marble has been used in many state capitols.

🏆 Famous American Quarries and Their Legacy

New Hampshire is called "The Granite State." That's the official nickname.

But for actual production volume? North Carolina, Texas, and Georgia lead the pack today.

🏆 Famous American Quarries and Their Legacy

✦ The Jefferson Memorial Connection

The Jefferson Memorial in Washington, D.C.? That's marble from Vermont's Danby Marble Quarry.

The Supreme Court building? Same source.

For over 100 years, Danby has been the choice for America's most important structures and iconic monuments.

✦ Mount Rushmore

Workers carved Mount Rushmore in place rather than quarrying and moving the stone. But it highlighted American granite. The Harney Peak granite used for those massive presidential faces is some of the hardest stone on Earth.

📜 The History of American Granite and Marble Quarrying

✦ Colonial Beginnings (1600s-1700s)

Granite quarrying started early in America. Settlers needed durable building materials. New England had plenty of granite deposits.

The first commercial quarries opened in Massachusetts in the 1600s. Workers used hand tools and black powder to extract blocks.

The North Carolina Granite Corporation started at Mount Airy in 1743. Still operating today, over 280 years later.

✦ The Golden Age (1800s-Early 1900s)

The 1800s brought explosive growth. Italian and Scottish immigrants arrived, master stonecutters with generations of expertise. They transformed the industry.

Vermont's marble industry boomed. The Danby Marble Quarry opened in the late 1800s. Vermont Marble Company became famous nationwide.

Massachusetts quarries thrived as Boston grew. Milford Pink defined the city's architecture. Chelmsford Gray became standard for infrastructure.

During this era, tens of thousands worked in quarries. Entire towns built economies around stone. Mount Airy literally became "The Granite City" because granite was everything. Skills passed from father to son.

✦ The Technology Revolution (Mid-1900s)

The mid-twentieth century brought machines. Diamond wire saws replaced hand tools. Hydraulic splitters eliminated manual labor. What took dozens of workers weeks now took a small crew days.

But efficiency cost jobs. The craft skills immigrants brought became less important. Family operations closed or sold to corporations. The industry shifted from artisan craft to industrial extraction.

✦ The Import Era (1970s-Present)

The 1970s and 80s changed everything. Brazilian and Indian quarries started flooding the American market. They operated at massive scale with low labor costs. They offered affordable, colorful granite.

American quarries couldn't compete on price for residential stone. The plain gray color from domestic sources served construction fine. But it couldn't match the blues, reds, and exotic patterns from overseas.

Quarries that supplied residential stone either shifted to dimension stone for construction or closed.

Today's industry looks nothing like its golden age. Most family operations have disappeared. Employment dropped from tens of thousands to a few thousand. Hand-cutting stone has nearly vanished.

⚙️ How Granite and Marble Are Quarried: From Mountain to Countertop

✦ Modern Granite Extraction

Today's quarrying mixes precision technology with raw power.

Diamond Wire Sawing: Modern quarries use steel cables embedded with industrial diamonds. These wires cut through dozens of feet of solid granite. A single cut might take hours or days for large blocks.

Drilling and Splitting: Workers drill lines of holes along where they want the break. Then hydraulic splitters or controlled explosives separate large sections from the mountain. When done right, massive granite breaks cleanly.

Block Extraction: Once workers separate the blocks, heavy machinery lifts them. These rough blocks weigh 10-20 tons or more. They ship to fabrication facilities for processing.

✦ Marble Quarrying Differences

Marble needs gentler treatment than granite. It's softer and fractures more easily.

Vermont's Danby operates underground for better control. Underground means less exposure to weather and temperature swings. Less risk of fracturing.

The underground chambers at Danby are massive. Some hold a football field. Craftsmen carved them carefully over decades.

Marble quarries use smaller equipment and move more slowly. Diamond wire saws work, but operators proceed cautiously. A crack acceptable in structural granite ruins marble intended for high-end use.

✦ The Journey to Your Kitchen

Rough blocks are just the start.

Transportation: Blocks travel by truck to fabrication facilities. For American quarries, that's regional fabricators. For imported stone, blocks go by ship for processing.

Cutting into Slabs: Large saws cut blocks into slabs, typically 2cm or 3cm thick for countertops. This uses diamond-tipped blades and water cooling. It takes hours per block. Each block yields 50-70 slabs.

Polishing and Finishing: Slabs go through multiple polishing stages. Start with coarse abrasives, progress to finer grits until glossy. Some get "leathered" or "honed" finishes instead of high polish.

Fabrication: Finally, shops like ours handle the stone fabrication. We measure your kitchen, cut slabs to size with CNC machines or water jets, create sink cutouts and edge profiles, then install the finished countertops.

✦ Technology's Impact

Modern quarrying looks nothing like the 1800s. Computer modeling plans extraction for maximum yield. GPS-guided equipment ensures precise cuts. Robotic systems handle material that once required dozens of workers.

Water jet cutting and diamond wire technology minimize waste. Environmental monitoring tracks dust, noise, and water use. Safety equipment has made the work far less dangerous.

Yet despite all this technology, American quarries still can't compete economically with overseas operations for residential stone. The technology is the same worldwide. The difference is scale and labor costs.

🌍 Why Most Countertop Stone Still Comes From Abroad

Even with great American quarries, importers bring in almost 90% of residential granite and marble. Most comes from Brazil, India, China, and Italy.

✦ The Color Problem

Most American granite comes in plain gray or neutral tones. Excellent for structural use, paving materials, dimension stone, and monuments.

But homeowners want variety. Dramatic veining. Exotic colors. Unique patterns. Brazilian quarries produce blues, reds, and multi-colored granites that make statement countertops. For those who prefer engineered options, quartz countertops offer consistent colors without the natural variation.

American granite quarries excel at reliable stone for commercial use. That plain gray serves construction needs perfectly. It's just not what people want in their dream kitchens.

✦ The Infrastructure Gap

The United States ranks 18th globally in granite and marble production. Behind Turkey, China, and India.

We don't have infrastructure to meet residential demand at competitive prices.

American quarries focus on dimension stone, natural stone cut to specific shapes for construction. The equipment and processes for residential slabs are concentrated overseas. Labor costs are lower there. They scale operations for global markets.

✦ Price Matters

Economics favor Brazilian and Indian granite for residential use. Lower labor costs. Established supply chains. Sheer production volume.

Imported slabs often cost less than American granite, even after shipping halfway around the world. For more details on what to expect, visit our pricing and quotes page.

🤝 Supporting Local: American Fabrication and Installation

Here's where you make a difference: choose a local countertop fabricator and installer, regardless of where the stone originated.

Even if your granite came from Brazil, working with local shops means:

Supporting local businesses and craftspeople in your community. Getting personalized service from experts who know your area. Ensuring proper installation by professionals trained in natural stone handling. Building relationships with people who'll be there for your next project.

Small shops across America employ skilled workers who transform imported slabs into beautiful countertops. The stone might travel thousands of miles from quarries in the USA or abroad. But the craftsmanship going into your kitchen is 100% local.

These local businesses continue America's natural stone tradition. Even when raw material comes from overseas quarries, installation quality remains distinctly American.

🧭 Choosing Your Countertop Stone

Whether you want granite's durability or marble's elegance, understanding where materials come from adds depth to your decision.

For granite countertops, you'll probably pick imported options. These often have richer colors and more dramatic patterns than most American quarries offer. That's perfectly fine, and what most homeowners prefer.

For marble lovers, Vermont produces world-class white marble. But the exotic marbles homeowners love (Calacatta, Carrara variations, dramatic veining) typically come from Italy or other international sources. Learn more about marble countertops and what to expect.

❓ Frequently Asked Questions About US Granite and Marble Quarries

Q. Where is granite found in the United States?

A. Granite is quarried in 34 states. The top five producers are Texas, Wisconsin, Massachusetts, Indiana, and Georgia, accounting for 64% of American production. North Carolina has the world's largest open-face granite quarry in Mount Airy.

Q. Where are marble quarries located in the US?

A. Major marble quarries are in Vermont (Danby, the world's largest underground marble quarry), Colorado (high-altitude Calacatta Lincoln), Georgia, Tennessee, Alabama, and Missouri. Vermont's Danby Marble Quarry supplied marble for the Jefferson Memorial and Supreme Court.

Q. What is the largest granite quarry in the world?

A. Mount Airy, North Carolina houses the world's largest open-face granite quarry. The North Carolina Granite Corporation has operated it since 1743, over 280 years of continuous production.

Q. Why is most countertop granite imported?

A. Three reasons: Most American granite is plain gray, excellent for construction but lacking colors homeowners want. The US lacks infrastructure to meet residential demand at competitive prices. And imported granite often costs less even after shipping, due to lower labor costs and massive production scale overseas.

Q. What American granites are good for countertops?

A. Virginia Mist and Jet Mist from Virginia are popular choices, offering attractive patterns and coloring. Dakota Mahogany from South Dakota provides rich red tones. Deer Isle granite from Maine features beautiful coloring for high-end applications.

Q. What is dimension stone?

A. Dimension stone is natural stone cut and finished to specific sizes for construction use. The United States is the world's top consumer of dimension stone, using it for building facades, monuments, and paving. Most American quarries focus on dimension stone rather than decorative slabs for residential countertops.

📚 Related Articles

🏠 Visit Our Southborough Showroom

At Granite Guy, we work with both American and imported natural stone. We help you find the right granite or marble for your project.

With over 30 years of experience and more than 10,000 installations in Greater Boston and MetroWest, we know stone. Whether you need kitchen countertops in Massachusetts or anywhere in New England, we understand where stone comes from, how it works, and how to make it shine in your home.

Stop by our countertop store at 43 Turnpike Road (Route 9), Southborough, MA 01772 during business hours. We keep a large inventory in our heated warehouse, so there's always plenty to see. You can also browse our live inventory online before you visit.

Already done your homework and know what you want? Email us or give us a call.

📞 508-460-7900

📧 info@graniteguyinc.com

Learn about our process and pricing